Welcome to the JeepSpecs.com in-depth page on the WK Generation Jeep Grand Cherokee’s engine features & specifications. Did we miss anything? Please get in touch with us and tell us about it!

WK engine features

3.0-liter Turbo Diesel (2007-2008*)

|

The 3.0-liter V-6 “common rail” direct injection engine is a 72°, overhead valve design. The engine utilize a cast aluminum cylinder block molded around cast iron piston sleeves. The engine has aluminum cross flow cylinder heads, four valves per cylinder, central injectors and dual overhead camshafts. The 3.0L is turbocharged, intercooled, and also equipped with a EGR cooler.

Additional features are:

Finger Follower Actuated Valves with Hydraulic Adjusters

Counter Rotating Balance Shaft

Oil Jet Cooled Pistons

Swirl Intake Ports

Chain driven D.O.H.C. per bank of cylinders, with 4 valves per cylinder

*2007, 2008 and 2008.5 model years only. Production of this engine ended in November 2008.

|

|

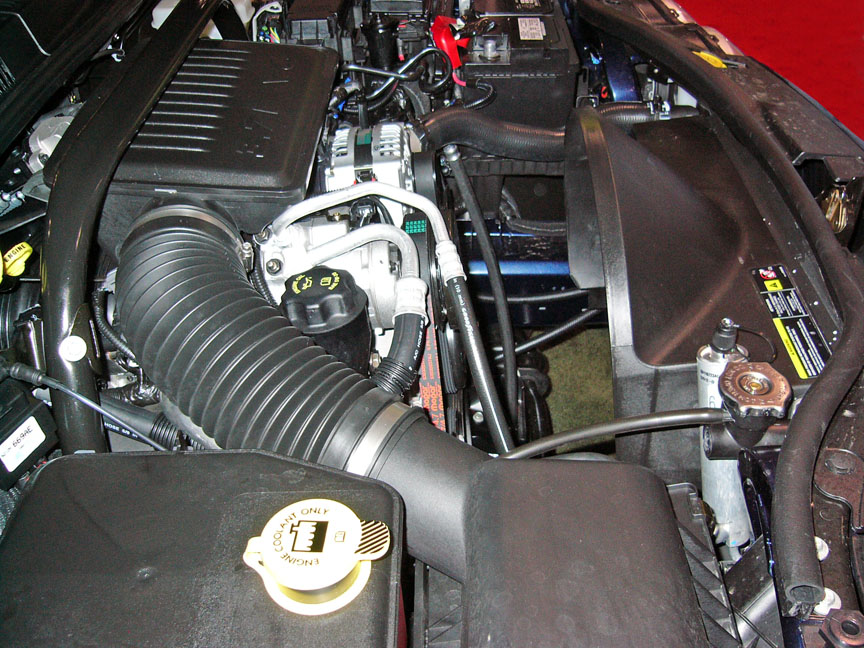

The 3.7-liter V-6 engine provides the 2005 Jeep Grand Cherokee with an efficient, durable and smooth base engine. It produces 210 hp (157 kW) @5200 rpm and 235 lb-ft (319 N•m) @4000 rpm. The 3.7-liter SOHC V-6 will replace and deliver even more peak power than the previous 4.0-liter I-6 in the Jeep Grand Cherokee lineup. The engine was first introduced in the Jeep Liberty and has been continuously refined to provide smooth V-6 power with optimal economy.

Significant changes in the 3.7-liter include a revised cam profile and new valve lash adjusters. These changes improve the engine smoothness at idle. To ensure quiet operation, a new thick-wall composite manifold is new for 2005, as are structural improvements to the air box and resonator. The cylinder head has been redesigned, increasing the compression ratio to 9.7:1. The 3.7-liter now uses plastic cylinder head covers.

|

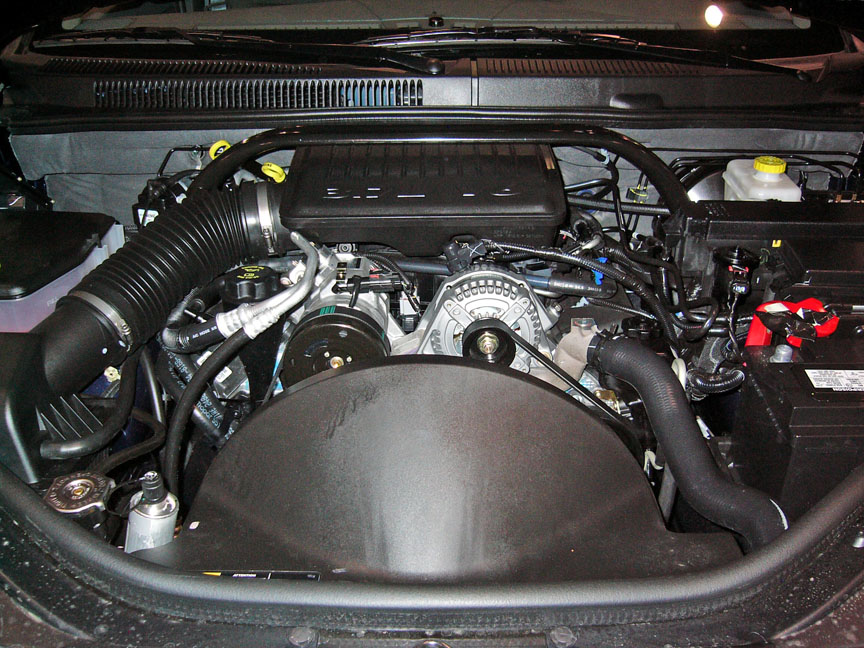

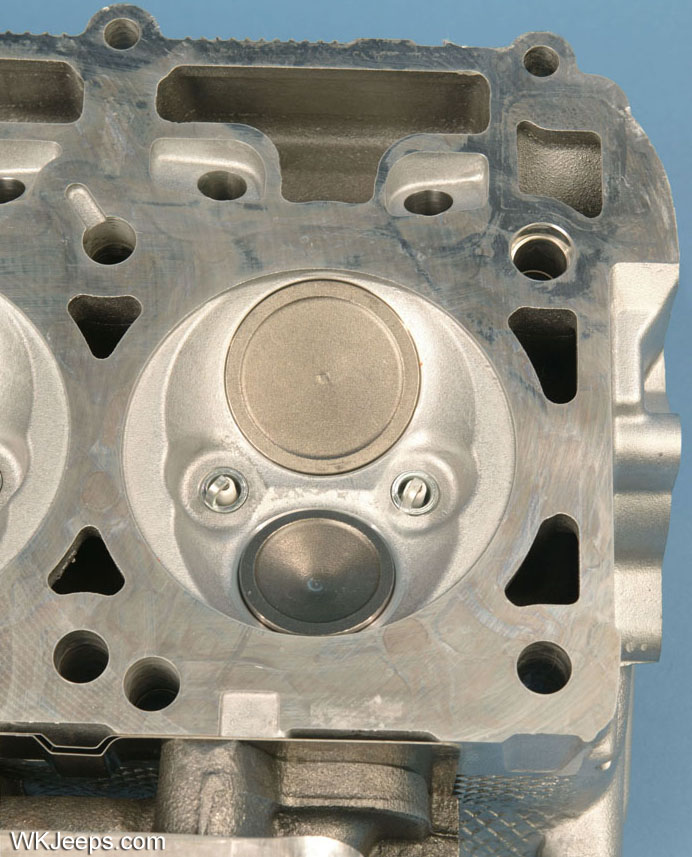

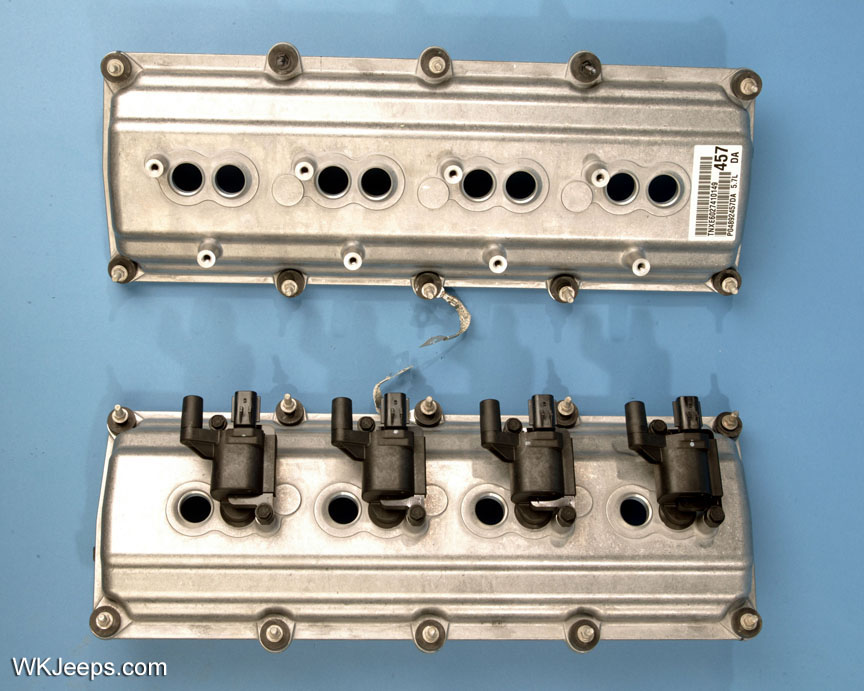

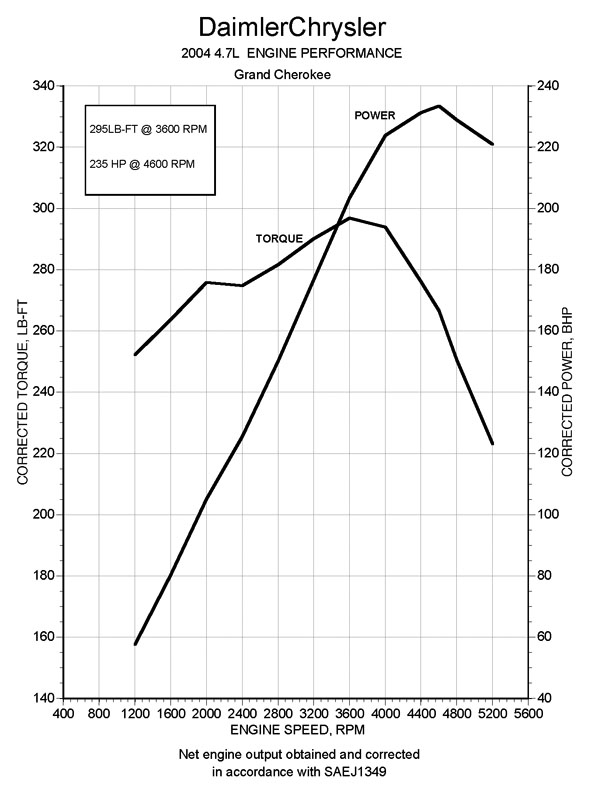

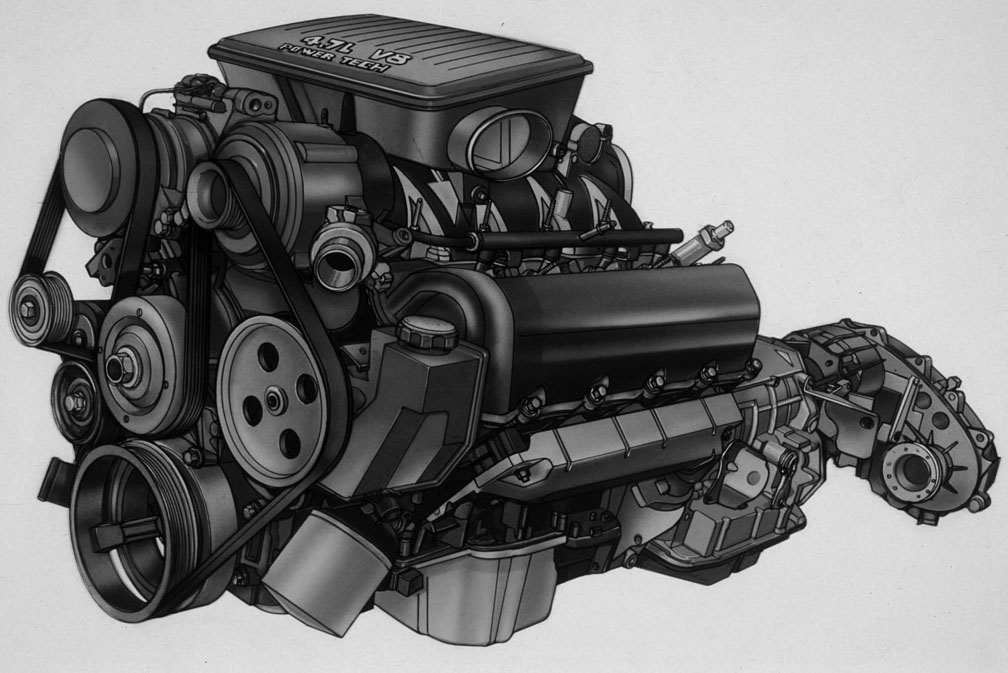

The 4.7-liter V-8 was updated for the 2005 model year and was the mid-range engine in 2005-2007 model Grand Cherokees. The engine produces 235 hp (172 kW) @ 4700 rpm and 290 lb-ft (393 N•m) of torque @ 3700. Dual knock sensors have been added for 2005 and enable improved engine calibration for both fuel economy and power output. The updated engine has improved NVH characteristics, realized through the use of composite valve covers, structural improvements to the air box and resonator and improved dampening of the heat shields. An EGR valve is now used to reduce NOX emissions while improving fuel economy by replacing some of the incoming fuel/air mixture with inert exhaust gas.

The Dana corporation supplied the new reduced-tension piston rings and the rod bearings. Dana also supplied the new cylinder-head, cam-cover module. The new thermoset plastic cylinder-head cover module was developed in just 12 months and replaces a magnesium component. Due to innovative manufacturing processes, Dana was able to reduce the overall cost of the module, while incrementally improving noise, vibration, and harshness, or NVH.

The vinyl ester glass-reinforced thermoset plastic modules, which are unique to the left- and right-side cylinders, include the cover, gasket, and fasteners. These components are produced at Dana’s Composite Sealing Center in Paris, Tenn. With this new sealing system, Dana developed a custom compound material for gaskets and grommets. Dana also provided prototyping for the gasket and isolator molds to ensure the design met all of Jeep’s specifications. The system relies on a self-retaining, “press-in-place” gasket to improve function and quality consistency. This innovation eliminates the time- consuming and costly steps of precisely aligning and attaching the gasket to the valve cover with adhesive.

Dana engineers worked closely with DaimlerChrysler’s technical staff to provide 3-D solid models to fit tight, under-the-hood requirements. Dana also provided material development and component validation to ensure robust system performance. This collaborative effort eliminated the prototype step for the cover housing, which in turn reduced development time and cost by allowing the component to move directly from design to production.

|

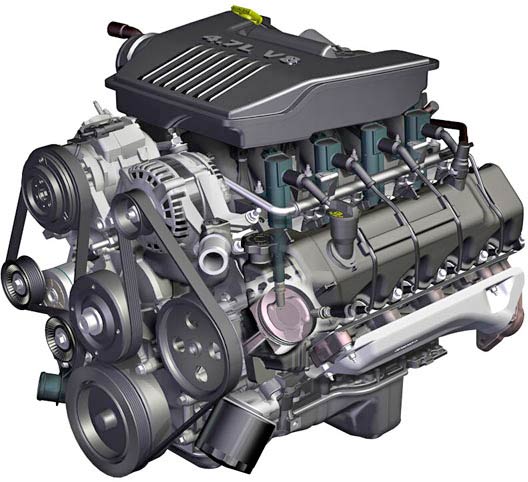

2008 models of the Grand Cherokee and Commander will feature a new updated 4.7-liter V-8. The new engine offers better fuel economy, power, and torque than the previous 4.7-liter engine, while increasing refinement, thanks to dual spark plugs per cylinder, increased compression, better cylinder-head port flow, and a new combustion system. The result is 305 horsepower, a 30 percent increase; and 334 lb.-ft. of torque, a 10 percent increase. The engine is still capable of operating on E85 ethanol fuel. Smoother and quieter running came from revisions to the induction system, a lightweight piston/rod assembly, reduced accessory drive noise through lower accessory drive speed, and a new valve-lash adjuster system. The new 4.7-liter V-8 is also equipped with Electronic Throttle Control.

|

The 5.7-Liter V-8 HEMI engine that powers the 2005-2008 Jeep Grand Cherokee uses aluminum cylinder heads with hemispherical combustion chambers, creating outstanding airflow leading to high power and torque. The engine produces 330 hp (246 kW) @5000 rpm and 375 lb-ft (502 N•m) @4000 rpm. Dual ignition (two spark plugs per cylinder) increases peak power and torque, reduces exhaust emissions, increases fuel economy and provides a smooth idle. The combustion system has been refined and the engine uses direct-mount accessories for quieter operation.

“Two legends combine with the introduction of the modern HEMI V-8 in the 2005 Jeep Grand Cherokee,” said Eric Ridenour, Executive Vice President—Product Development. “The HEMI is the most powerful engine ever offered in a Grand Cherokee and easily gives the vehicle best-in-class power.”

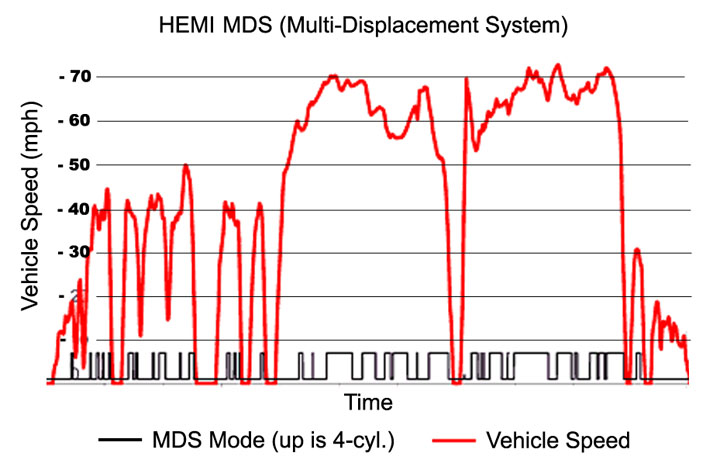

Fuel economy has also been improved, but not at the expense of HEMI performance. Chrysler Group has developed the Multi-Displacement System (MDS) that deactivates four cylinders when the V-8 is not needed. The 2005 Grand Cherokee is the first SUV to offer fuel-conserving MDS.

The Chrysler Group MDS seamlessly alternates between smooth and economic four-cylinder mode when less power is needed and V-8 mode when more power from the 5.7-liter HEMI engine is in demand. This optimizes fuel economy when V-8 power is not needed without sacrificing vehicle performance or towing capability.

“The MDS was part of the engine’s original design,” said Bob Lee, Vice President—Powertrain Product Team. “This results in a cylinder deactivation system that is elegantly simple and completely integrated into the engine design. The benefits are fewer parts, maximum reliability and lower cost.”

Some of the significant technologies enabling the MDS are the speed of electronic controls, the sophistication of the algorithms controlling the systems and the use of Electronic Throttle Control. The HEMI is able to transition from eight cylinders to four in 40 milliseconds.

This engine and MDS has completed over 6.5 million customer-equivalent miles through Chrysler Group’s development and durability testing. It is covered by the seven-year/70,000-mile Limited Powertrain warranty.

The HEMI engine that powers the 2005 Jeep Grand Cherokee uses aluminum cylinder heads with hemispherical combustion chambers, creating outstanding airflow leading to high power and torque. Dual ignition (two spark plugs per cylinder) increases peak power and torque, reduces exhaust emissions, increases fuel economy and provides a smooth idle. The combustion system has been refined and the engine uses direct-mount accessories for quieter operation.

|

|

|

|

|

|||||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

The all-new 2nd generation 5.7-liter HEMI V-8 engine offers better fuel economy, improved idle quality and overall refinement, along with more horsepower and torque. HEMI has always been synonymous with power, and now – thanks to VVT, expanded four-cylinder mode in the MDS system, and a host of other technologies – Chrysler’s new HEMI delivers more fuel efficiency and refinement, along with even more power. Other enhancements include an increased compression ratio and an active intake manifold with long runners for low-end torque and short runners for high-rpm power. The cylinder head port flow efficiency has also been improved.

The HEMI’s new VVT improves fuel economy under some conditions in two ways. First, it reduces the engine’s pumping work by closing the intake valve later. Second, it increases the expansion process of the combustion event. This allows more work to be transferred to the crankshaft instead of being rejected out of the exhaust port as heat. Essentially, VVT optimizes engine breathing, which improves engine efficiency and power.

The fuel-saving MDS system seamlessly alternates between smooth, high- fuel-economy four-cylinder mode when less power is needed, and V-8 mode when more power from the new 5.7-liter HEMI engine is in demand. An expanded MDS operating range in the new-for-2009 HEMI will allow customers to realize an even-greater fuel economy benefit. When MDS is operating, it is indicated by the fuel-economy- mode readout in the Electronic Vehicle Information Center.

|

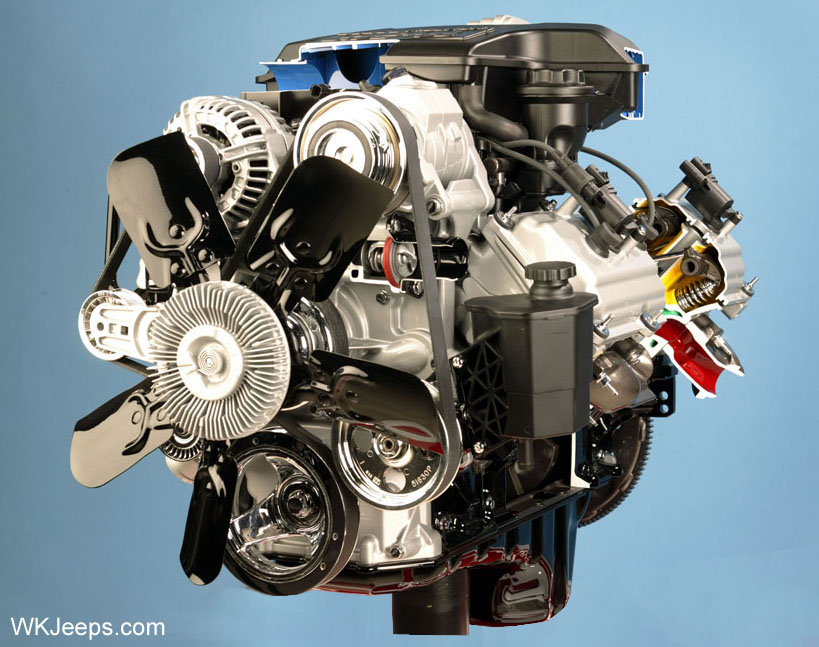

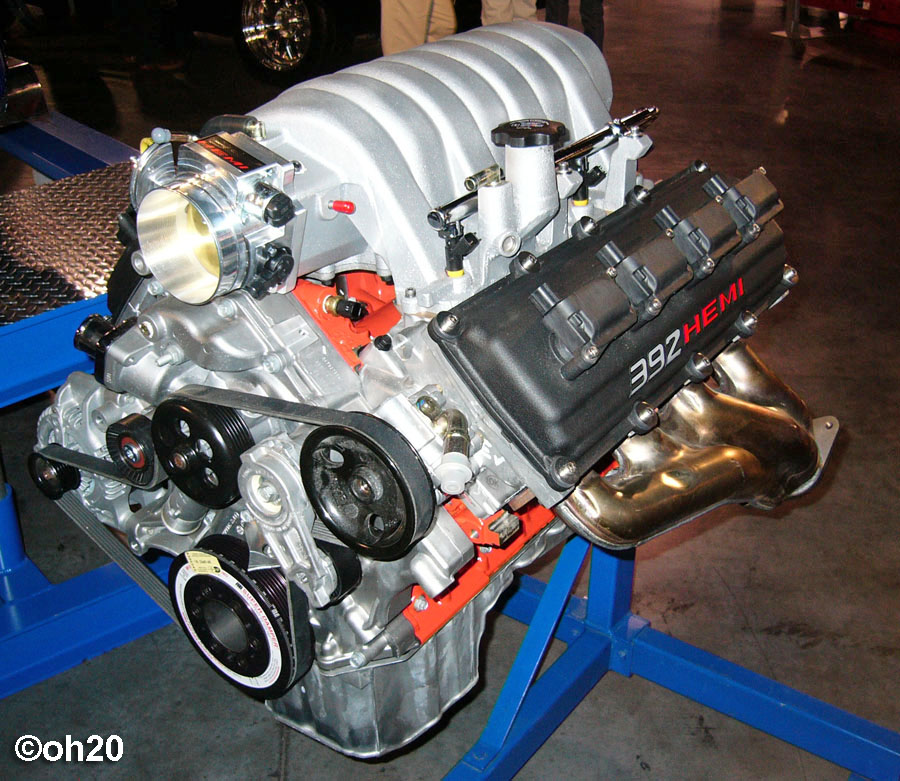

The 6.1L-liter V8 HEMI made its Jeep debut in the 2006 Grand Cherokee SRT8 which went on sale in January of 2006. When SRT powertrain engineers set out to develop a more powerful HEMI they were mindful of the engine’s heritage, which led to adopting traditional HEMI engine cues including an orange-painted cylinder block and black valve covers. SRT engineers who developed the 6.1L engine achieved more horsepower by adding more cubic inches, increasing the compression ratio, and redesigning the cylinder head, intake and exhaust systems for better flow and increased engine speed.

For more displacement, SRT engineers bored out the diameter of the cylinders in the HEMI by 3.5 millimeters each in order to increase the total displacement to 6.1 liters from 5.7 liters. Compression ratio was also increased to 10.3:1 from 9.6:1, increasing engine efficiency and power. Cylinders are honed with torque plates to ensure a truer bore, to reduce friction and increase power.

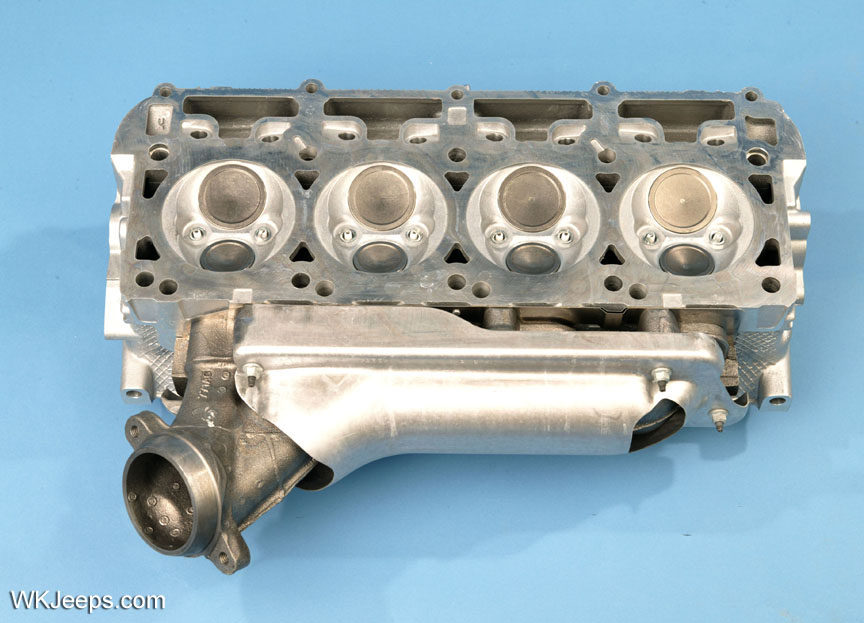

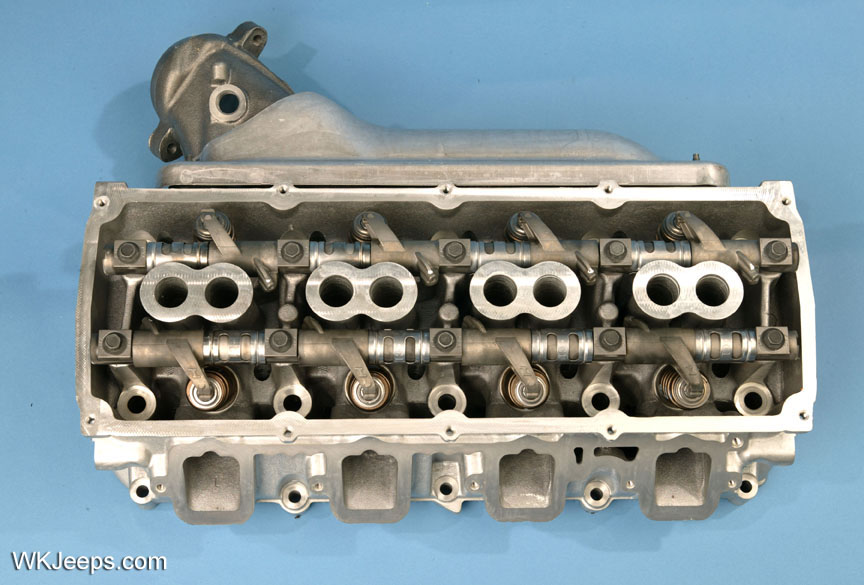

Engine breathing was increased with new higher-flow cylinder heads, a specially designed intake manifold, and exhaust headers with individual tubes encased in a stainless steel shell, all unique to the 6.1-liter HEMI engine. Larger-diameter valves and reshaped ports in the heads allow for maximized air flow. The intake manifold was designed with larger diameter and shorter runners for higher-speed tuning. Exhaust runners allow increased gas flow while maintaining fast catalyst light-off, while adding 12 horsepower over the 5.7-liter engine’s cast manifolds. Exhaust is routed through a large diameter (2.75-inch vs. 2.5-inch) exhaust system with 3.5-inch chrome tips.

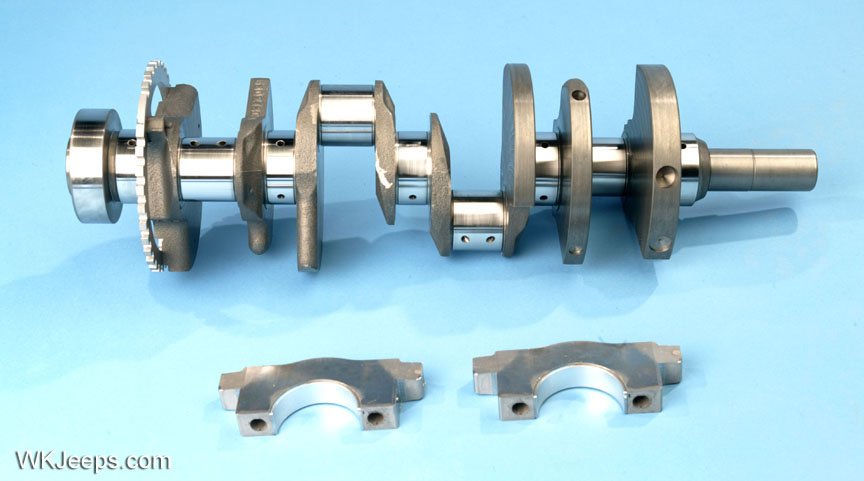

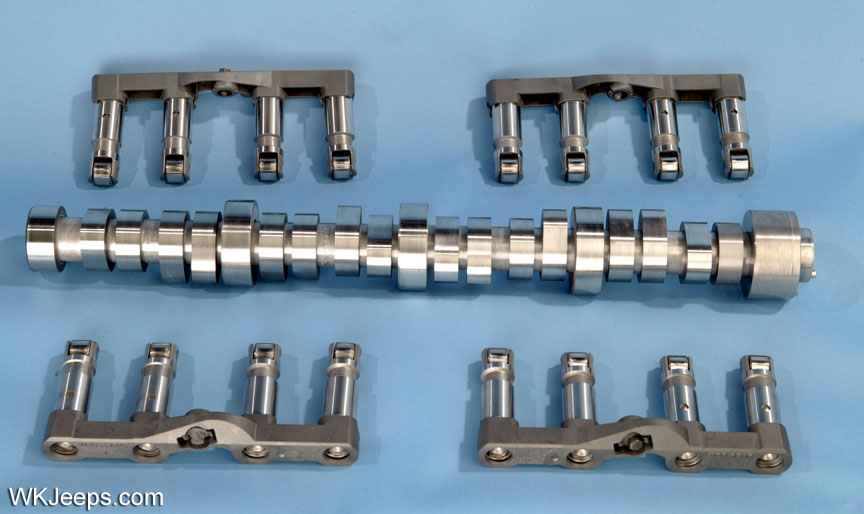

To further increase horsepower, performance-oriented camshaft profiles were developed to allow more air in and out of the cylinders, as well as manage a higher engine speed. A billet steel, high-strength camshaft features more overlap and lift for better performance. Silent chain, 5-bearings. Bi-metal material except number 3 Babbit. Deep-fillet rolled journals for improved fatigue life, press fit damper to minimize torsional vibration.

SRT engineers increased the HEMI’s peak power output engine speed by nearly 20 percent to 6,000 revolutions per minute (rpm) from 5,000 rpm. Intake and exhaust valve stems are hollow, and the exhaust valve stems are filled with sodium to help dissipate heat more efficiently.

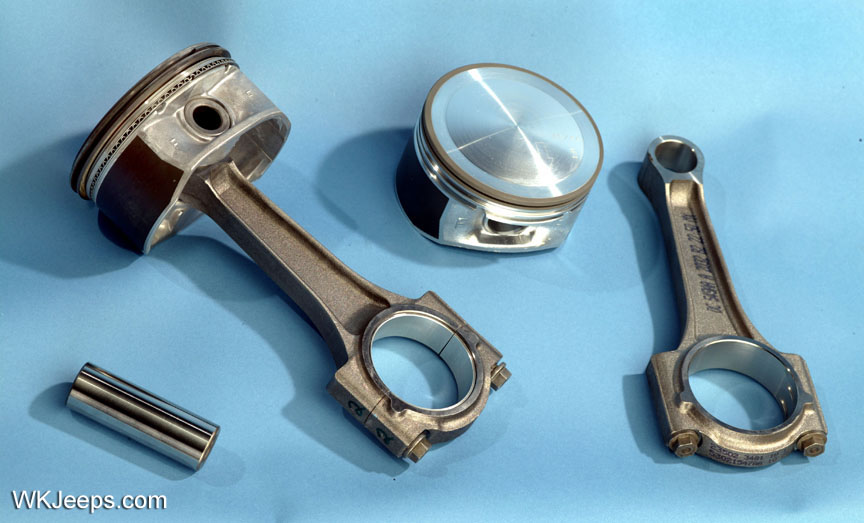

The high-performance SRT 6.1-liter HEMI is strengthened with redesigned components, including a reinforced engine block, forged micro-alloy steel crankshaft with retuned damper, high-strength powdered metal connecting rods and floating-pin pistons. The pistons are cooled by oil squirters, aimed at the underside of each piston to aid piston cooling for engine durability. A special oil pump pressure relief valve is added to accommodate the squirter oil flow. The oil pan and windage tray are modified to manage oil return to the pan sump at high engine speeds and improve power.

|

A 6.4L-liter V8 HEMI with MDS has been approved for production and will debut in SRT8 models of the 2011 Challenger, the 2011 Charger and the 2011 300C. The Jeep Grand Cherokee will also receive this engine in the 2012 model year. The production version of the 6.4 engine is expected to produce anywhere from 470-hp to 510-hp.

3.7L V8 4.7L V8 4.7L V8 Gen II

|

||||||||||||

| Description | 3.7-L V6 (2005-2010) | 4.7-L V8 (2005-2007) | 4.7-L V8 Gen II (2008-2010) | |||||||||

| General | ||||||||||||

| Air cleaner element / Intake system | Standard air intake system | Standard air intake system | Standard air intake system | |||||||||

| Bore x stroke | 93.0 mm (3.66 in.) 90.8mm (3.57 in.) |

93.0 mm (3.66 in.) 86.5mm (3.40 in.) |

93.0 mm (3.66 in.) 86.5mm (3.40 in.) |

|||||||||

| Coolant capacity | 14.0 qt. (13.25-liter) | 14.0 qt. (13.25-liter) | 14.0 qt. (13.25-liter) | |||||||||

| Compression Ratio | 9.7:1 | 9.0:1 | 9.8:1 | |||||||||

| Displacement | 3.7 Liters / 226 C.I. | 4.7 Liters / 287 C.I. | 4.7 Liters / 287 C.I. | |||||||||

| Engine type | 90° SOHC V-6 | 90° SOHC V-8 | 90° SOHC V-8 | |||||||||

| Engine speed, maximum | 5800 RPM | 6000 RPM | 6000 RPM | |||||||||

| Engine speed, tachometer redline | 5300 RPM | |||||||||||

| Firing Order | 1-6-5-4-3-2 | 1-8-4-3-6-5-7-2 | 1-8-4-3-6-5-7-2 | |||||||||

| Fuel requirement | Regular unleaded, 87 octane | Regular unleaded, 87 octane | Regular unleaded, 87 octane E85 compatible |

|||||||||

| Injectors | flow = 22.5 lb/hr @ 49psi | |||||||||||

| Knock sensor(s) | Two (Stereo) | Two (Stereo) | Two (Stereo) | |||||||||

| Lead Cylinder | # 1 Left Bank | # 1 Left Bank | # 1 Left Bank | |||||||||

| Oil Capacity | 5 Quarts(5W-30) | 6 Quarts(5W-30) | 6 Quarts(5W-30) | |||||||||

| Oil pressure | At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

At curb idle: 04 psi minimum @3000 rpm: 25 psi |

At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

|||||||||

| Power (SAE net) | 211 BHP @ 5200 RPM | 235 BHP @ 4800 RPM | 305 BHP @ 5650 RPM | |||||||||

| Spark plugs | Type: ZFR6F-11G (NGK)Standard resistor-type

OEM P/N SPZFR6F11G MSRP: $3.30 ea. 0.43 in. gap 3/4″ reach, 5/8″ Hex head Torque to 20 Ft. lbs.

|

Type: RC12MCC4“Fired in suppressor seal” spark plugs using a copper core ground electrode.

OEM P/N SPRC12MCC4 MSRP: $3.30 ea. 0.40 in. gap 3/4″ reach, 5/8″ Hex head Torque to 20 Ft. lbs. (NOTE: The 4.7L V–8 engine is equipped with copper core ground electrode spark plugs. They must be replaced with the same type/number spark plug as the original. If another spark plug is substituted, preignition will result.)

|

Type: FR8TE2 (intake) Type: FR8T1332 (exhaust) Bosch Nickel Yttrium plugs (intake) Bosch Iridium plugs (exhaust)OEM P/N 5149050AB (intake side) OEM P/N 5149888AA (exhaust side)MSRP: $0.00 ea.0.40 in. gap (intake) 0.50 in. gap (exhaust)??” reach, 5/8″ Hex head?Torque to 20 Ft. lbs. CAUTION: This engine uses TWO DIFFERENT types of spark plugs. A total of 16 plugs is used. The plugs are mounted in two rows (banks). The upper row is used on the intake valve side of the cylinder head. The lower row is used on the exhaust valve side of the cylinder head. The upper row uses Bosch Nickel Yttrium plugs. The lower row uses Bosch Iridium plugs. DO NOT INTERCHANGE THESE PLUGS.

|

|||||||||

| Torque (SAE net) | 235 LB-FT @ 4000 RPM | 295 LB-FT @ 3200 RPM | 334 LB-FT @ 3950 RPM | |||||||||

| Valve system | Chain-driven SOHC, 12 valves and hydraulic end-pivot roller rockers | Chain-driven SOHC, 16 valves, hydraulic end-pivot roller rockers | Chain-driven SOHC, 16 valves, hydraulic end-pivot roller rockers | |||||||||

| Valve lift (zero lash) | Intake 12.00 mm (0.472 in.) Exhaust 12.00 mm (0.472 in.) |

Intake 11.25 mm (0.443 in.) Exhaust 10.90 mm (0.4292 in.) |

Intake 11.25 mm (0.443 in.) Exhaust 10.90 mm (0.4292 in.) |

|||||||||

| Valve springs (intake and exhaust unless noted) |

7.30 coils (intake) 7.15 coils (exhaust) |

6.69 coils 4.28 mm wire diameter |

7.30 coils 4.60 mm x 3.67 mm wire diameter |

|||||||||

| Cylinder Block etc. | ||||||||||||

| Camshaft | Bore Diameter 26.02-26.04 mm (1.0245-1.0252 in.)Bearing Journal Diameter 25.975-25.995 mm (1.0227-1.0235 in.)Bearing Clearance 0.025-0.065 mm (0.001-0.0026 in.)End Play (MAX) .200 mm (0.0079 in.) |

Bore Diameter 26.02 – 26.04 mm (1.0245 – 1.0252 in.)Bearing Journal Diameter 25.975 – 25.995 mm (1.0227 – 1.0235 in.)Bearing Clearance 0.025 – 0.065 mm (0.001 – 0.0026 in.)End Play .075 – .200 mm (0.003 – 0.0079 in.) |

Bore Diameter 26.02 – 26.04 mm (1.0245 – 1.0252 in.)Bearing Journal Diameter 25.973 – 25.995 mm (1.0227 – 1.0235 in.)Bearing Clearance 0.025 – 0.065 mm (0.001 – 0.0026 in.)End Play .075 – .200 mm (0.003 – 0.0079 in.) |

|||||||||

| Crankshaft | Out of Round 0.005 mm (0.0002 in.)End Play 0.052 – 0.282 mm (0.0021 – 0.0112 in.)Bearing Clearance 0.006 – 0.044 (0.0002 – 0.0011 in.)Taper (max.) 0.006 mm (0.0004 in.) |

Out of Round (max.) 0.005 mm (0.0004 in.)End Play 0.052 – 0.282 mm (0.0021 – 0.0112 in.)Bearing Clearance 0.004 – 0.034 mm (0.0002 – 0.0013 in.)Taper (max.) 0.008 mm (0.0004 in.) |

Out of Round (max.) 0.005 mm (0.0004 in.)End Play 0.052 – 0.282 mm (0.0021 – 0.0112 in.)Bearing Clearance 0.004 – 0.034 mm (0.0002 – 0.0013 in.)Taper (max.) 0.008 mm (0.0004 in.) |

|||||||||

| Cylinder Block | Cast-iron block and bedplate Aluminum alloy heads |

Cast-iron block Aluminum alloy heads |

Cast-iron block Aluminum alloy heads |

|||||||||

| Main bearings | Journal diameter 63.488 – 63.512 mm (2.4996 – 2.5005 in.) |

Journal diameter 63.488 – 63.512mm (2.4996 – 2.5005 in.)Bi-metal construction |

Journal diameter 63.488 – 63.512mm (2.4996 – 2.5005 in.)Bi-metal construction |

|||||||||

| Pistons | ||||||||||||

| Diameter | 92.975 mm (3.6605 in.) | 92.975 mm (3.6606 in.) | 92.975 mm (3.6605 in.) | |||||||||

| Material | Aluminum Alloy | Aluminum Alloy | ||||||||||

| Weight | 365.0 grams (12.87 oz.) | 367.5 grams (12.96 oz.) | 366.0 grams (12.90 oz.) | |||||||||

| Piston Pins | ||||||||||||

| Clearance in Piston | 0.006 – 0.015 mm (0.0002 – 0.0005 in.) |

0.010 – 0.019 mm (0.0004 – 0.0008 in.) |

0.010 – 0.019 mm (0.0004 – 0.0008 in.) |

|||||||||

| Diameter | 24.017 – 24.020 mm 0.9455 – 0.9456 in.) |

24.017 – 24.020 mm (0.9455 – 0.09456 in.) |

24.013 – 24.016 mm (0.9454 – 0.09455 in.) |

|||||||||

| Type | Pressed Fit | Pressed Fit | ||||||||||

| Valve Timing | ||||||||||||

| Intake – Opens (ATDC) | 4.4° | 4.4° | ||||||||||

| Intake – Closes (ATDC) | 240.1° | 239.1° | 239.1° | |||||||||

| Intake – Duration | 245.7° | 243.5° | 243.5° | |||||||||

| Exhaust – Opens (BTDC) | 241.5° | 240.5° | 240.5° | |||||||||

| Exhaust – Closes (ATDC) | 20.1° | 13.2° | 13.2° | |||||||||

| Exhaust – Duration | 261.6° | 253.70° | 253.70° | |||||||||

| Valve Overlap | 25.7° | 17.6° | 17.6° | |||||||||

| Top speed | ||||||||||||

| 3.7-L V-6 | 4.7-L V-8 | 4.7-L V-8 Gen II | ||||||||||

| 0-60 mph | 7.2 (Car & Driver)7.46 (Motor Trend)7.49 (AMSI, 1999 WJ) |

|||||||||||

| 0-62 mph (0-100 km/h) | 9.0 (DaimlerChrysler) |

|||||||||||

| 1/4 mile / speed | 15.6 / 86.0 mph (Car & Driver)15.74 / 85.4 mph (Motor Trend)15.46 / ? mph (AMSI, 99 WJ)15.93 / 84.3 mph (Private owner “Doanlaw”, 99 WJ) |

|||||||||||

| Top speed (w/ limiter) | 114 mph | |||||||||||

| Top speed (w/o limiter) | 124 mph (DaimlerChrysler) |

|||||||||||

| Curve charts | ||||||||||||

|

||||||||||||

|

|||||||||||

| Description | 3.0L CRD | 5.7L V8 (2005-2008) Gen I

5.7L V8 (2009-2010) Gen II |

6.1L V8 HEMI | ||||||||

| General | |||||||||||

| Air cleaner element / Intake system | Dry Filter with Turbocharger and Charge Air Cooler | Low restriction air intake system | Low restriction air intake system | ||||||||

| Bore x stroke | 83 mm(3.26 in.) 92.0mm (3.62 in.) |

99.5mm (3.92 in.) 90.9mm (3.58 in.) |

103mm (4.06 in.) 90.9mm (3.58 in.) |

||||||||

| Coolant capacity | 14.0 qt. (13.30-liters) | 14.5 qt. (13.72-liters) | 14.0 qt. (13.25-liters) | ||||||||

| Compression Ratio | 18.0:1 | 9.6:1

10.5:1 |

10.3:1 | ||||||||

| Displacement | 3.0 Liters / 182 C.I. | 5.7 Liters / 345 C.I. | 6.1 Liters / 370 C.I. | ||||||||

| Engine type | CRD | 90° V-8 HEMI | 90° V-8 HEMI | ||||||||

| Engine speed, maximum | 5800 RPM | 6400 RPM | |||||||||

| Engine speed, tachometer redline | |||||||||||

| Firing Order | 1-4-2-5-3-6 | 1-8-4-3-6-5-7-2 | 1-8-4-3-6-5-7-2 | ||||||||

| Fuel requirement | Diesel | Mid-grade 89 octaneAcceptable: Regular grade, 87 octanePremium is NOT recommended |

Premium 91 octane (R+M)/2 recommended | ||||||||

| Injectors | flow = 22.5 lb/hr @ 49psi | ||||||||||

| Knock sensor(s) | Two (Stereo) | Two (Stereo) | |||||||||

| Lead Cylinder | # 1 Left Bank | # 1 Left Bank | # 1 Left Bank | ||||||||

| Oil Capacity | 10 quarts | 7 Quarts(Note: 5W-20 oil MUST be used for proper operation of MDS system) | 7 Quarts0W-40 (API rated SL/CF full synthetic engine oil such as Mobile 1) | ||||||||

| Oil pressure | At curb idle: 16 psi @3200 rpm: 52 psi |

At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

At curb idle: 04 psi minimum @3000 rpm: 25-110 psi |

||||||||

| Power (SAE net) | 215 BHP @ 4200 RPM | 325-330 BHP @ 5000 RPM

357 BHP @ 5200 RPM |

420 BHP @ 6200 RPM | ||||||||

| Spark plugs | P/N SPRE14MCC4 MSRP: $3.25Type: RE14MCC40.45 in. gap 1″ reach, 5/8″ Hex head Torque to 12-14 Ft. Lbs. (*NOTE: The 5.7L V-8 is equipped with torque critical tapered design spark plugs. Do not exceed 15 ft. lbs. torque.)

P/N SLZFR5C11G Type: LZFR5C11G4 0.43 in. gap (*NOTE: The 5.7L Gen II V-8 is equipped with torque critical tapered design spark plugs. Do not exceed 15 ft. lbs. torque.) |

P/N SPLZTR5A13 MSRP: $0.00Type: LZTR5A130.50 in. gap 1″ reach, 5/8″ Hex head Torque to 12-14 Ft. Lbs. (*NOTE: The 6.1L V-8 is equipped with torque critical tapered design spark plugs. Do not exceed 15 ft. lbs. torque.) |

|||||||||

| Torque (SAE net) | 376 LB-FT @ 1800 RPM | 370-375 LB-FT @ 3500 RPM

389 LB-FT @ 4350 RPM |

420 LB-FT @ 4800 RPM | ||||||||

| Weight, engine | 474 Lbs. (215 Kg) | ||||||||||

| Cylinder Block etc. | |||||||||||

| Camshaft | Chain Driven Dual Overhead Camshafts | End play .080 – 0.290mm (0.0031 – 0.0114 in.)Type Hollow Assembled |

End play .080 – 0.290mm (0.0031 – 0.0114 in.)Type Hollow Assembled |

||||||||

| Crankshaft | Out of round 0.005 mm (0.0002 in.)End play 0.052 – 0.282 mm (0.002 – 0.011 in.)Bearing Clearance 0.020 – 0.060 mm (mm 0.0007 – 0.0023 in.)Taper (max.) 0.003 mm (0.0001 in.)Material Nodular iron |

Out of round 0.005 mm (0.0002 in.)End play 0.052 – 0.282 mm (0.002 – 0.011 in.)Bearing Clearance 0.023 – 0.051 mm (0.0009 – 0.002 in.)Taper (max.) 0.003 mm (0.0001 in.)Material Nodular iron |

|||||||||

| Cylinder Block | Deep-skirt cast-iron block with cross-bolted main bearing caps Aluminum alloy heads with hemispherical combustion chambers. |

Deep-skirt cast-iron block with cross-bolted main bearing caps Aluminum alloy heads with hemispherical combustion chambers |

|||||||||

| Main bearings | Journal diameter 64.988 – 65.012 mm (2.5585 – 2.5595 in.) |

Journal diameter 64.988 – 65.012 mm (2.5585 – 2.5595 in.) |

|||||||||

| Hydraulic tappets | |||||||||||

| Body diameter | 21.387 – 21.405 mm (0.8420 -0.8427 in.) |

21.387 – 21.405 mm (0.8420 -0.8427 in.) |

|||||||||

| Clearance (to bore) | 0.020 – 0.063 mm (0.0007 – 0.0024 in.) 0.020 – 0.063 mm |

0.020 – 0.063 mm (0.0007 – 0.0024 in.) |

|||||||||

| Dry lash | 3.0 mm at the valve (0.1181 in. at the valve) |

3.0 mm at the valve (0.1181 in. at the valve) |

|||||||||

| Pistons | |||||||||||

| Diameter | 82.833 (82.839 mm) | ||||||||||

| Material | Aluminum Alloy | Aluminum Alloy | |||||||||

| Weight | 413 grams (14.56 oz.) | 435 grams (15.34 oz.) | |||||||||

| Piston Pins | |||||||||||

| Clearance in Piston | 0.009 – 0.018 mm (0.00035 – 0.0007 in.) |

0.006 – 0.015 mm (0.00023 – 0.00059 in.) |

|||||||||

| Diameter | 24.0 – 24.003 mm (0.9448 – 0.9449 in.) |

25.0 – 25.003 mm (0.9843 – 0.9844 in.) |

|||||||||

| Valves | |||||||||||

| Valve system | Pushrod-operated overhead valves, 16 valves, eight deactivating and eight conventional hydraulic lifters, all with roller followers.

Variable-valve Timing (VVT), pushrod-operated overhead valves, 16 valves, eight deactivating and eight conventional hydraulic lifters, all with roller followers. |

Pushrod-operated overhead valves, 16 valves, eight conventional hydraulic lifters, all with roller followers. Intake valves feature hollow stems and 2 mm larger heads compared to the 5.7L engine, allowing more air flow. | |||||||||

| Valve lift (zero lash) | Intake 12.00 mm (0.472 in.) Exhaust 11.70 mm (0.460 in.) |

Intake 14.50 mm (0.571 in.) Exhaust 14.00 mm (0.551 in.) |

|||||||||

| Valve springs (intake and exhaust unless noted) |

7.4 coils 5.39 × 4.52 mm wire diameter 7.95 coils VALVE SPRING NOTE: |

7.35 coils 5.65 × 4.51 mm wire diameter Premium valve springs with external dampers enhance the valvetrain and enable higher engine speed operation to 6,400 rpm |

|||||||||

| Valve Timing | |||||||||||

| Intake – Opens (BTDC) | 5.0°

21.7° |

15.0° | |||||||||

| Intake – Closes (ATDC) | 253.0°

255.0° |

268.0° | |||||||||

| Intake – Duration | 258°

269.3° |

283.0° | |||||||||

| Exhaust – Opens (BTDC) | 233.0°

236° |

251.0° | |||||||||

| Exhaust – Closes (ATDC) | 27.0°

32.0° |

35.0° | |||||||||

| Exhaust – Duration | 253.7°

269.0° |

286.0° | |||||||||

| Valve Overlap | 34.0°

39.5° |

50.0° | |||||||||

| Top speed | |||||||||||

| 3.0-L V-6 | 5.7-L V-8 | 6.1-L V-8 HEMI | |||||||||

| 0-60 mph | 4.7 sec. | ||||||||||

| 1/4 mile / speed | 13.5 sec. | ||||||||||

| Top speed (w/ limiter) | 165 mph | ||||||||||

| Top speed (w/o limiter) | 165 mph | ||||||||||

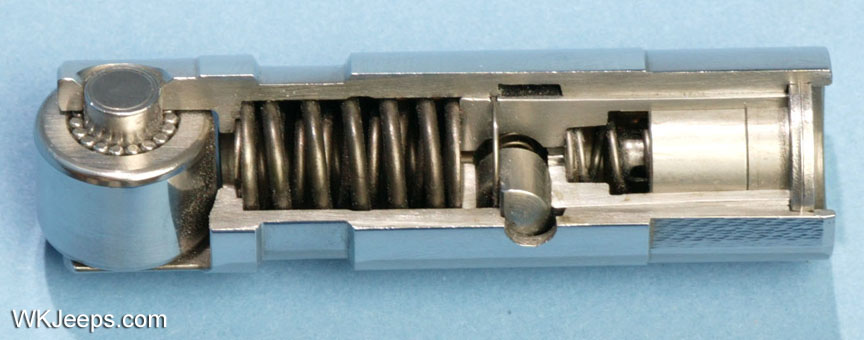

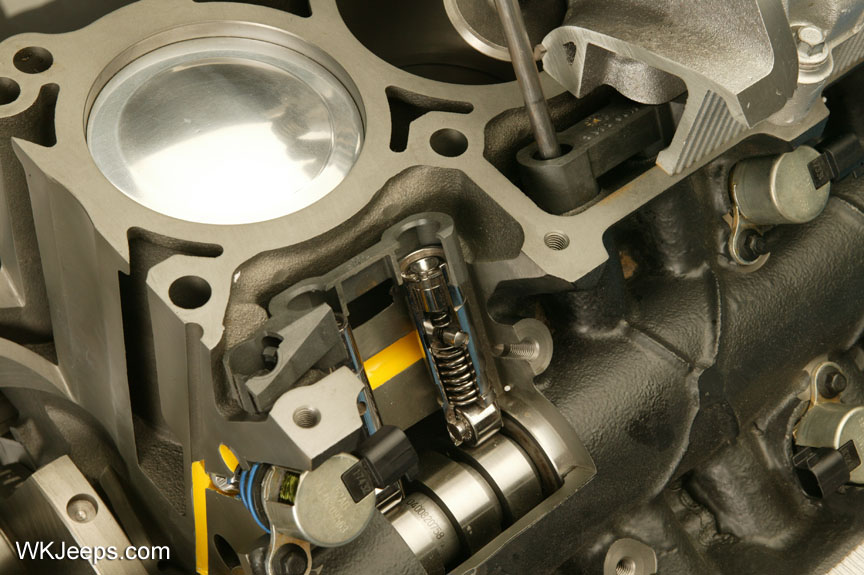

The Chrysler Group MDS is standard equipment with the 5.7L HEMI on seven vehicles: the Chrysler 300C, Dodge Charger R/T, Durango, Magnum R/T, Ram 1500 and Jeep Grand Cherokee and Commander. With the addition of MDS to HEMI-equipped Dodge Durango and Ram, MDS-equipped vehicles through the end of the 2007 model year will save more than 60 million gallons of fuel each year. The Chrysler Group MDS (Multi-Displacement System) seamlessly alternates between smooth, high fuel economy four-cylinder mode when less power is needed, and V-8 mode when more power from the 5.7L HEMI® engine is in demand,” said Eric Ridenour, Executive Vice President Product Development, Chrysler Group. “This optimizes fuel economy when V-8 power is not needed, without sacrificing vehicle performance. The MDS was part of the engine’s original design,” said Bob Lee, Vice President Powertrain Product Team, Chrysler Group. “This resulted in a cylinder-deactivation system that is elegantly simple and completely integrated into the engine design. The benefits are fewer parts, maximum reliability and lower cost. Some of the significant technologies enabling the Chrysler Group MDS are the speed of electronic controls, the sophistication of the algorithms controlling the systems and the use of Electronic Throttle Control. The HEMI will be able to transition from eight cylinders to four in 40 milliseconds (0.040 seconds). The HEMI engine with MDS has completed over 6.5 million customer- equivalent miles through Chrysler Group’s development and durability testing. It is covered by the 7-Year/70,000-mile Limited Powertrain warranty. The system deactivates the valve lifters. This keeps the valves in four cylinders closed, and there is no combustion. In addition to stopping combustion, energy is not lost by pumping air through these cylinders. For proper operation, 5w-20 oil must be used in engines with the MDS feature. Failure to do so may result in improper operation of the Multiple Displacement System. Customers will experience estimated fuel economy gains of up to 20 percent under various driving conditions, and a projected 10 percent aggregate improvement. Improved fuel economy is realized without any change in customer experience — drivers will receive the benefit without changing their driving habits and without compromising style, comfort or convenience. MDS components and operation The Multiple Displacement System (MDS) provides cylinder deactivation during steady speed, low acceleration and shallow grade climbing conditions to increase fuel economy. Both four and eight cylinder configurations have even firing intervals providesmooth operation. Two cylinders on each bank are active when the engine is in four-cylinder mode – every other cylinder in the firing order. All of the cylinders that are deactivated have unique hydraulic valve lifters that collapse when deactivated to prevent the valves from opening. Engine oil pressure is used to activate and deactivate the valves. It is delivered through special oil passages drilled into the cylinder block. Solenoid valves control the flow. When activated, pressurized oil pushes a latching pin on each valve lifter, which then becomes a “lost motion” link. Its base follows the camshaft, but its top remains stationary, held in place against the pushrod by light spring pressure but unable to move because of the much higher force of the valve spring. Deactivation occurs during the compression stroke of each cylinder, after air and fuel enter the cylinder. Ignition then occurs, but the combustion products remain trapped in the cylinder under high pressure, because the valves no longer open. No air enters or leaves. During subsequent piston strokes, this high-pressure gas is repeatedly compressed and expanded like an air spring, but fuel is not injected. The Multi Displacement System selectively deactivates cylinders 1,4,6, and 7, to improve fuel economy. It has two modes of operation:

The main components of the Multi Displacement System are:

The MDS system is designed to operate at speeds from around 20 mph to 80 mph. Some owners have reported activation at speeds up towards 90 mph. As shown in the chart below, the duty cycle is more active at highway speeds and on level ground. Other parameters that owners have discovered is that the engine operating temperature must be at least 130 degrees and oil pressure above 45 psi. In addition, the transmission must be in 5th gear at speeds above 35-40 mph. MDS “activation lights” have been added by some owners. This involves wiring up a small light and switch to the No. 4 cylinder MDS solenoid power wire at the PCM pin # 28. While some people can determine the point when MDS is engaged or disengaged by the sound of the exhaust (more notably on aftermarket exhaust systems), the light provides more exacting results as to when the MDS system is on or off. Cylinder Deactivation

Cylinder Reactivation

Just a few simple tips can help owners of Chrysler Group engines with Multi-Displacement System (MDS) get the most fuel mileage possible from their 5.7L HEMI® V8 engine. The customer does not need to drive in a certain way to realize a fuel economy improvement with MDS, but these driving habits can maximize their fuel savings with this technology.

|