Welcome to the JeepSpecs.com in-depth page on the WK Generation Jeep Grand Cherokee spark plugs. Did we miss anything? Please get in touch with us and tell us about it!

| 3.7-L V6 (2005-2010) (standard on Laredo) |

4.7-L V8 (2005-2007) (standard on Limited, optional on Laredo) |

4.7-L V8 (2008-2010) (standard on Limited, optional on Laredo) |

| Type: ZFR6F-11G (NGK)Standard resistor-type

OEM P/N SPZFR6F11G MSRP: $3.70 ea. .042 in. gap 3/4″ reach, 5/8″ Hex head Torque to 20 Ft. lbs.

|

Type: RC12MCC4“Fired in suppressor seal” spark plugs using a copper core ground electrode.

OEM P/N SPRC12MCC4 MSRP: $3.70 ea. .040 in. gap 3/4″ reach, 5/8″ Hex head Torque to 20 Ft. lbs. (NOTE: The 4.7L V–8 engine is equipped with copper core ground electrode spark plugs. They must be replaced with the same type/number spark plug as the original. If another spark plug is substituted, preignition will result.)

|

Type: FR8TE2 (intake) Type: FR8T1332 (exhaust)Bosch Nickel Yttrium plugs (intake) Bosch Iridium plugs (exhaust)OEM P/N SPFR8TE2AA (intake side) OEM P/N SPFR8TI332 (exhaust side)MSRP: $4.60 ea. (intake side) MSRP $8.10 ea. (exhaust side) .040 in. gap (intake side) ??” reach, 5/8″ Hex head Torque to 20 Ft. lbs. CAUTION: This engine uses TWO DIFFERENT types of spark plugs. A total of 16 plugs is used. The plugs are mounted in two rows (banks). The upper row is used on the intake valve side of the cylinder head. The lower row is used on the exhaust valve side of the cylinder head. The upper row uses Bosch Nickel Yttrium plugs. The lower row uses Bosch Iridium plugs. DO NOT INTERCHANGE THESE PLUGS. |

| 5.7-L V8 HEMI (2005-2008) (standard on Overland, optional on Limited) |

5.7-L V8 HEMI VCT (2009-2010) (standard on Overland, optional on Limited) |

6.1-L V8 HEMI (2006-2010) (standard on SRT8) |

| Type: RE14MCC4(Champion 570)

OEM P/N SPRE14MCC4 MSRP: $4.10 ea. .045 in. gap 1″ reach, 5/8″ Hex head Torque to 12-14 Ft. lbs.* * Torque critical tapered design. Do not exceed 15 ft. lbs.

|

Type: LZFR5C11G(NGK)

OEM P/N SPLZFR5C11 MSRP: $4.20 ea. .040 in. gap ?” reach, 5/8″ Hex head Torque to 12-14 Ft. lbs.* * Torque critical tapered design. Do not exceed 15 ft. lbs.

|

Type: PLZTR5A13(NGK Double-Platinum 4998)

OEM P/N SPLZTR5A13 MSRP: $11.45 ea. .040 in. gap 1″ reach (25mm, .984″), 5/8″ Hex head, heat range 5 Torque to 12-14 Ft. lbs.* * Torque critical tapered design. Do not exceed 15 ft. lbs. |

3.7L V-6 ENGINE

The 3.7L V-6 engine uses a separate ignition coil for each cylinder. The one-piece coil bolts directly to the cylinder head. Rubber boots seal the secondary terminal ends of the coils to the top of all 6 spark plugs. A separate electrical connector is used for each coil.

Because of coil design, spark plug cables (secondary cables) are not used. A distributor is not used with the 3.7L engine.

Two knock sensors (one for each cylinder bank) are used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery voltage to each ignition coil.

The ignition system consists of:

6 Spark Plugs

6 Separate Ignition Coils

2 Knock Sensors

Powertrain Control Module (PCM)

Also to be considered part of the ignition system are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position, 2 knock and MAP Sensors.

4.7L V-6 ENGINE (2005-2007)

The 4.7L V-8 engine uses a separate ignition coil for each cylinder. The one-piece coil bolts directly to the cylinder head. Rubber boots seal the secondary terminal ends of the coils to the top of all 8 spark plugs. A separate electrical connector is used for each coil.

Because of coil design, spark plug cables (secondary cables) are not used. A distributor is not used with the 4.7L engine.

Two knock sensors (one for each cylinder bank) are used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery voltage to each ignition coil.

The ignition system consists of:

8 Spark Plugs

8 Separate Ignition Coils

2 Knock Sensors

Powertrain Control Module (PCM)

Also to be considered part of the ignition system are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position, 2 knock and MAP Sensors.

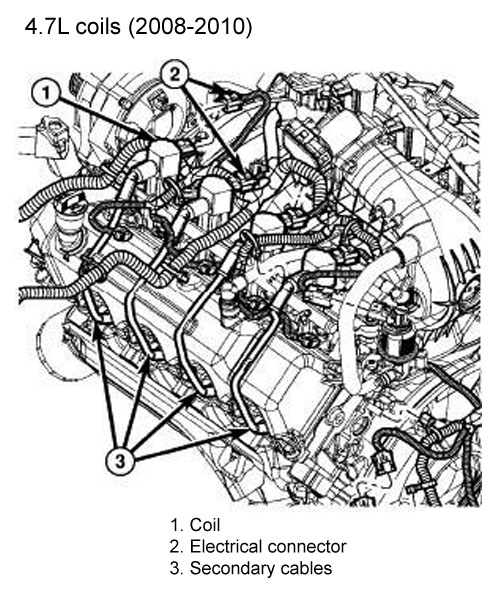

4.7L V-6 ENGINE (2008-2010)

The 4.7L V-8 engine uses a separate ignition coil for each cylinder. The one-piece coil bolts directly to the cylinder head. Rubber boots seal the secondary terminal ends of the coils to the top of all 8 spark plugs. A separate electrical connector is used for each coil.

Because of coil design, spark plug cables (secondary cables) are not used. A distributor is not used with the 4.7L engine.

Two knock sensors (one for each cylinder bank) are used to help control spark knock.

The Auto Shutdown (ASD) relay provides battery voltage to each ignition coil.

The ignition system consists of:

16 Spark Plugs (2 per cylinder)

8 Separate Ignition Coils

2 Knock Sensors

Powertrain Control Module (PCM)

Also to be considered part of the ignition system are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position, 2 knock and MAP Sensors.

5.7L V-8 HEMI ENGINE (2005 models)

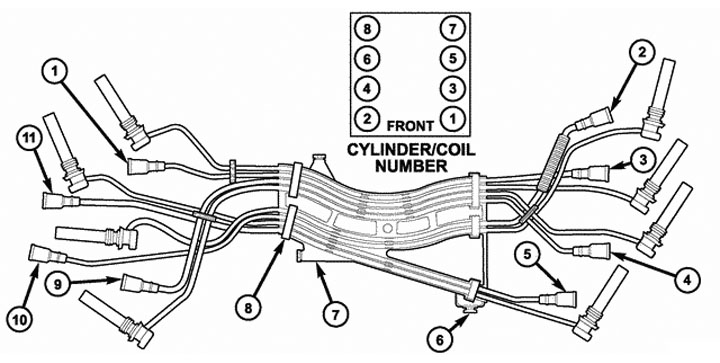

Spark plug/coil wire harness assembly. When the plugs fire after compression for the cylinder on the power stroke, the companion cylinder on the opposite bank fires during the exhaust stroke, requiring only eight ignition coils to fire all 16 spark plugs.

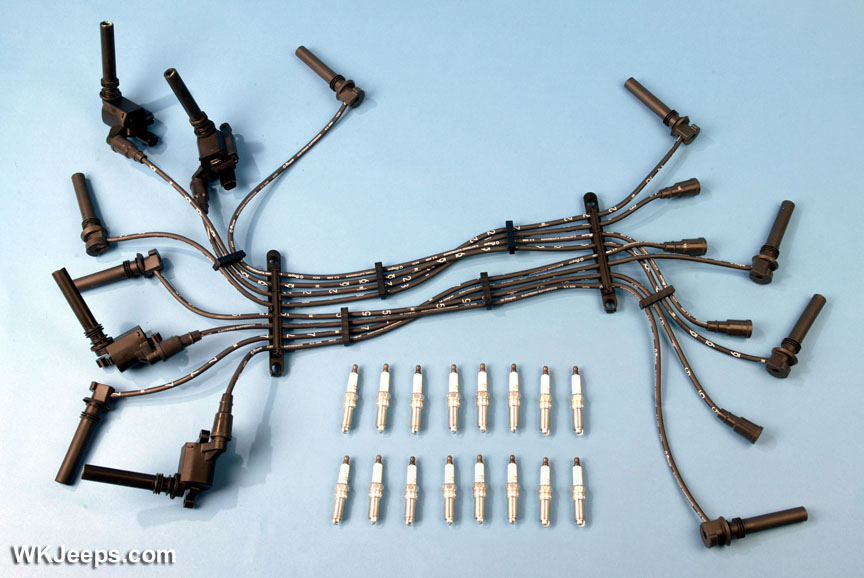

The 5.7L V-8 engine is equipped with 16 spark plugs. Two plugs are used for each cylinder. The 5.7L is also equipped with 8 separate and independent ignition coils. The one-piece coil bolts directly to the cylinder head cover and attaches the coils secondary output terminal directly to a spark plug using a rubber boot seal. Each coil is also equipped with a second output terminal. This second terminal connects a conventional spark plug cable directly to a spark plug on the opposite cylinder bank. A separate primary electrical connector is used for each coil.

Eight conventional spark plug cables are used with the 5.7L. These cables connect a coil on one cylinder bank, directly to a spark plug on the opposite cylinder bank. The cables are placed and routed in a special plastic loom to keep them separated. This loom is clipped to the intake manifold. To prevent a mismatch of cables, a corresponding spark plug / coil number is displayed on each plug cable: 1/6, 2/3, 4/7 and 5/8. These numbers and can also be found on the top of the intake manifold to the right of the throttle body.

Two knock sensors (one for each cylinder bank) are used to help control spark knock.

The 5.7L engine does not use a conventional distributor.

The ignition system consists of:

16 Spark Plugs (2 per cylinder)

8 Separate, Dual-Secondary Output, Ignition Coils

2 Knock Sensors

8 Secondary Ignition Cables

Powertrain Control Module (PCM)

Also to be considered part of the ignition system are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position, 2 knock and MAP Sensors.

5.7L V-8 HEMI ENGINE (2006-2010 models, plug cables eliminated)

The 5.7L V-8 engine is equipped with 16 spark plugs. Two plugs are used for each cylinder. The 5.7L is also equipped with 8 separate and independent ignition coils. The one-piece coil bolts directly to the cylinder head cover and attaches the coils secondary output terminal directly to a spark plug using a rubber boot seal. A separate primary electrical connector is used for each coil.

Two knock sensors (one for each cylinder bank) are used to help control spark knock.

The 5.7L engine does not use a conventional distributor.

The ignition system consists of:

16 Spark Plugs (2 per cylinder)

8 Separate, Dual-Secondary Output, Ignition Coils

2 Knock Sensors

Powertrain Control Module (PCM)

Also to be considered part of the ignition system are certain inputs from the Crankshaft Position, Camshaft Position, Throttle Position, 2 knock and MAP Sensors.

Spark plug installation and removal

Removing plugs – 3.7L engine

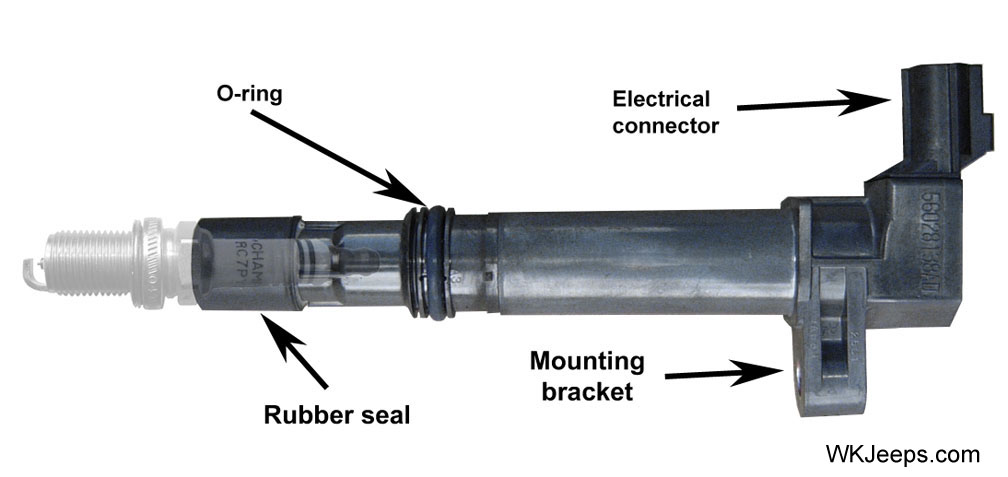

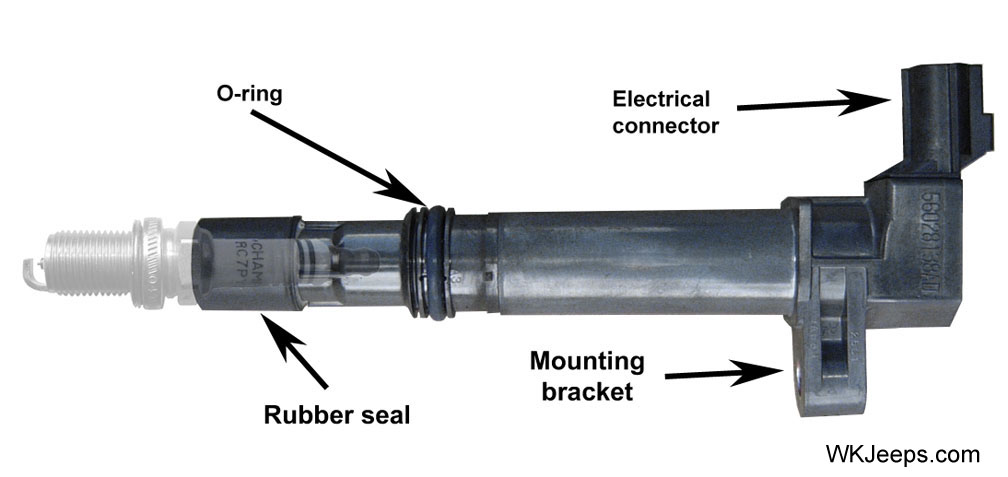

Each individual spark plug is located under each ignition coil. Each individual ignition coil must be removed to gain access to each spark plug. The coil fits into machined holes in the cylinder head. A mounting stud/nut secures each coil to the top of the intake manifold. The bottom of the coil is equipped with a rubber boot to seal the spark plug to the coil. Inside each rubber boot is a spring. The spring is used for a mechanical contact between the coil and the top of the spark plug. These rubber boots and springs are a permanent part of the coil and are not serviced separately. An o-ring is used to seal the coil at the opening into the cylinder head.

1. Remove necessary air filter tubing at throttle body.

2. Prior to removing ignition coil, spray compressed air around coil base at cylinder head.

3. Depending on which coil is being removed, the throttle body air intake tube or intake box may need to be removed to gain access to coil.

4. Disconnect electrical connector from coil by pushing downward on release lock on top of connector and pull connector from coil.

5. Clean area at base of coil with compressed air before removal.

6. Remove coil mounting nut from mounting stud.

7. Carefully pull up coil from cylinder head opening with a slight twisting action.

8. Remove coil from vehicle.

9. Prior to removing spark plug, spray compressed air into cylinder head opening. This will help prevent foreign material from entering combustion chamber.

10. Remove spark plug from cylinder head using a quality socket with a rubber or foam insert. Also check condition of ignition coil o-ring and replace as necessary.

Installing plugs – 3.7L engine

Special care should be taken when installing spark plugs into the cylinder head spark plug wells. Be sure the plugs do not drop into the plug wells as electrodes can be damaged.

Always tighten spark plugs to the specified torque. Over tightening can cause distortion resulting in a change in the spark plug gap or a cracked porcelain insulator.

1. Check and adjust spark plug gap with a gap gauging tool.

2. Start the spark plug into the cylinder head by hand to avoid cross threading.

3. Tighten spark plugs to 20 Ft. lbs. torque.

4. Before installing ignition coil(s), check condition of coil o-ring and replace as necessary. To aid in coil installation, apply silicone to the coil o-ring.

5. Position ignition coil into cylinder head opening and push onto spark plug. Do this while guiding coil base over mounting stud.

6. Install coil mounting stud nut.

7. Connect electrical connector to coil by snapping into position.

8. If necessary, install throttle body air tube.

|

Removing plugs – 4.7L engine (2005-2007)

Each individual spark plug is located under each ignition coil. Each individual ignition coil must be removed to gain access to each spark plug. The coil fits into machined holes in the cylinder head. A mounting stud/nut secures each coil to the top of the intake manifold. The bottom of the coil is equipped with a rubber boot to seal the spark plug to the coil. Inside each rubber boot is a spring. The spring is used for a mechanical contact between the coil and the top of the spark plug. These rubber boots and springs are a permanent part of the coil and are not serviced separately. An o-ring is used to seal the coil at the opening into the cylinder head.

1. Remove necessary air filter tubing at throttle body.

2. Prior to removing ignition coil, spray compressed air around coil base at cylinder head.

3. Depending on which coil is being removed, the throttle body air intake tube or intake box may need to be removed to gain access to coil.

4. Disconnect electrical connector from coil by pushing downward on release lock on top of connector and pull connector from coil.

5. Clean area at base of coil with compressed air before removal.

6. Remove coil mounting nut from mounting stud.

7. Carefully pull up coil from cylinder head opening with a slight twisting action.

8. Remove coil from vehicle.

9. Prior to removing spark plug, spray compressed air into cylinder head opening. This will help prevent foreign material from entering combustion chamber.

10. Remove spark plug from cylinder head using a quality socket with a rubber or foam insert. Also check condition of ignition coil o-ring and replace as necessary.

Installing plugs – 4.7L engine (2005-2007)

CAUTION: The 4.7L V–8 engine is equipped with copper core ground electrode spark plugs. They must be replaced with the same type/number spark plug as the original. If another spark plug is substituted, preignition will result.

Special care should be taken when installing spark plugs into the cylinder head spark plug wells. Be sure the plugs do not drop into the plug wells as electrodes can be damaged.

Always tighten spark plugs to the specified torque. Over tightening can cause distortion resulting in a change in the spark plug gap or a cracked porcelain insulator.

1. Check and adjust spark plug gap with a gap gauging tool.

2. Start the spark plug into the cylinder head by hand to avoid cross threading.

3. Tighten spark plugs to 20 Ft. lbs. torque.

4. Before installing ignition coil(s), check condition of coil o-ring and replace as necessary. To aid in coil installation, apply silicone to coil o-ring.

5. Position ignition coil into cylinder head opening and push onto spark plug. Do this while guiding coil base over mounting stud.

6. Install coil mounting stud nut.

7. Connect electrical connector to coil by snapping into position.

8. If necessary, install throttle body air tube.

4.7L engine coil (2005-2007)

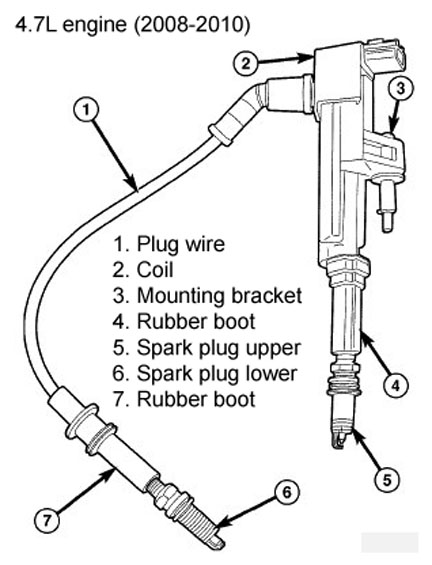

Removing plugs – 4.7L engine (2008-2010)

CAUTION: This engine uses TWO DIFFERENT types of spark plugs. A total of 16 plugs is used. The plugs are mounted in two rows (banks). The upper row is used on the intake valve side of the cylinder head. The lower row is used on the exhaust valve side of the cylinder head. The upper row uses Bosch Nickel Yttrium plugs. The lower row uses Bosch Iridium plugs. DO NOT INTERCHANGE THESE PLUGS.

CAUTION: Do not attempt to clean any of the spark plugs. Replace only.

1. Remove necessary air filter tubing and air intake components at top of engine and at throttle body.

2. To remove the upper row of plugs, each individual ignition coil must first be removed. Prior to removing ignition coil, spray compressed air around coil base at cylinder head.

3. Prior to removing spark plug, spray compressed air into cylinder head opening. This will help prevent foreign material from entering combustion chamber.

CAUTION: Due to tight clearances between UPPER row of plugs and cylinder head, a conventional deep, thick-wall spark plug socket will not fit. Use a deep, THIN-WALL 5/8” spark plug socket for plug removal and installation.

|

Installing plugs – 4.7L engine (2008-2009)

CAUTION: This engine uses TWO DIFFERENT types of spark plugs. A total of 16 plugs is used. The plugs are mounted in two rows (banks). The upper row is used on the intake valve side of the cylinder head. The lower row is used on the exhaust valve side of the cylinder head. The upper row uses Bosch Nickel Yttrium plugs. The lower row uses Bosch Iridium plugs. DO NOT INTERCHANGE THESE PLUGS.

CAUTION: Never use a motorized wire wheel brush to clean spark plugs. Metallic deposits will remain on spark plug insulator and will cause plug misfire.

CAUTION: Do not attempt to clean any of the spark plugs. Replace only.

1. Check and adjust spark plug gap with a gap gauging tool. Two different gaps are used.

2. To aid in coil installation, apply silicone based grease such as Mopar® Dielectric Grease into spark plug end of rubber boots. Also apply this grease to the tops of spark plugs.

3. Start the spark plug into the cylinder head by hand to avoid cross threading. Special care should be taken when installing spark plugs into the cylinder head spark plug wells. Be sure the plugs do not drop into the plug wells as electrodes can be damaged.

CAUTION: Due to tight clearances between upper row of plugs and cylinder head, a conventional deep, thick-wall spark plug socket will not fit. Use a deep, THIN-WALL 5/8” spark plug socket for plug removal and installation.

4. Install ignition coil(s).

5. Install necessary air filter tubing and air intake components to top of engine and to throttle body.

|

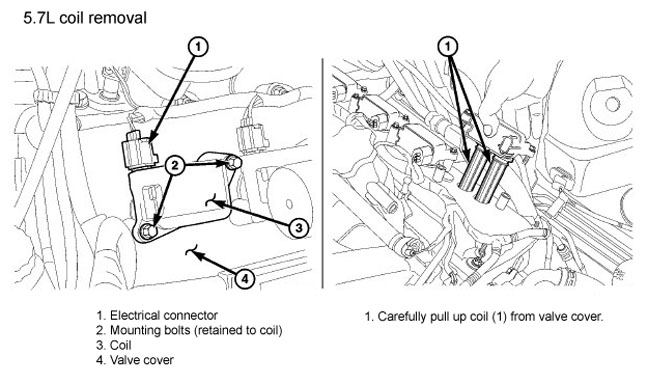

| Removing plugs – 5.7L and 6.1L engines

Each individual spark plug is located under each ignition coil. Each individual ignition coil must be removed to gain access to each spark plug. The coil mounts to the top of the valve cover with two bolts. The bottom of the coil is equipped with a rubber boot to seal the spark plug to the coil. Inside each rubber boot is a spring. The spring is used for a mechanical contact between the coil and the top of the spark plug. 1. Remove, if necessary, air filter tubing at throttle body. 2. Unlock the coil electrical connector by moving slide lock first. Press on release lock while pulling electrical connector from coil. 3. Prior to removing ignition coil, spray compressed air around coil base at cylinder head. 4. Remove two mounting bolts (note that mounting bolts are retained to coil). 5. Carefully pull up coil from cylinder head opening with a slight twisting action. 6. Remove coil from vehicle. 7. Prior to removing spark plug, spray compressed air into cylinder head opening. This will help prevent foreign material from entering combustion chamber. 8. Remove spark plug from cylinder head using a quality socket with a rubber or foam insert. Also check condition of ignition coil o-ring and replace as necessary. Installing plugs – 5.7L and 6.1L engines Special care should be taken when installing spark plugs into the cylinder head spark plug wells. Be sure the plugs do not drop into the plug wells as electrodes can be damaged. 1. Check and adjust spark plug gap with a gap gauging tool. 2. Start the spark plug into cylinder head by hand to avoid cross threading the aluminum threads. To aid in installation, attach a piece of rubber hose, or an old spark plug boot to the spark plug. 3. The 5.7L and 6.1L engines are equipped with torque critical design spark plugs. Tighten spark plugs to 12-14 Ft. lbs. Do not exceed 15 ft. lbs. torque. 4. Install ignition coil(s) to necessary spark plugs. 5. Before installing spark plug cables to either the spark plugs or coils, or before installing a coil to a spark plug, apply dielectric grease to inside of boots and the top of the spark plug. 6. Position ignition coil into cylinder head opening and push onto spark plug. Twist coil into position. 7. Install 2 coil mounting bolts. Tighten to 62 in. lbs. 8. Connect electrical connector to coil by snapping into position.

Spark plug cables on the 5.7L engine are paired on cylinders 1/6, 2/3, 4/7 and 5/8. Before removing or disconnecting any spark plug cables, note their original position . Remove cables one-at-a-time. To prevent ignition crossfire, spark plug cables MUST be placed in cable tray (routing loom) into their original position. The cable retention clips (6) and (8) must also be securely locked. If cable tray removal is necessary, release the 4 tray-to-manifold retention clips.

|